Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

-

To become a powerful injection molding enterprise, you must purchase a large number of injection molding machines, manipulators and auxiliary machines, and introduce professional processing technology talents, which requires a lot of capital.

time2018/11/04

-

The working principle of the injection molding machine is similar to the syringe used for injection. It uses the thrust of the screw (or plunger) to inject the plasticized molten state (that is, the viscous flow state) plastic into the closed mold cavity. The process of obtaining products after curing and setting.

time2018/12/21

-

The advantage of this system is that customers can access important information anytime, anywhere from anywhere in the world.

time2019/01/10

-

The injection molding machine is divided into a plunger injection molding machine and a screw injection molding machine according to the plasticizing method. According to the transmission mode of the machine, it can be divided into a hydraulic type, a mechanical type, and a hydraulic-mechanical (connecting rod) type. , Semi-automatic, manual injection molding machine.

time2019/02/14

-

3.1 Action program of injection molding machine

Clamping → Pre-molding → Reverse → Nozzle forward → Injection → Holding pressure → Nozzle backward → Cooling → Mold opening → Ejection → Door opening → Take workpiece → Door closing → Mold closing.time2020/07/23

-

In 1932, the German FRANEBRAUN factory manufactured an automatic plunger horizontal injection machine. With the development of the polymer industry, the injection molding process and injection molding machine have also been continuously improved and developed.

time2019/02/28

-

The process of making plastic mold bai:

Plan review-preparation-processing-mold frame du processing-mold core zhi processing-electrode processing-mold parts processing-inspection-assembly dao-flying mold-trial mold-production.time2020/03/26

-

Always check whether the injection molding machine is set up and running at the temperature specified on the record sheet. this is very important. Because the temperature will affect the surface finish and output of injection molded parts. All measured values must be recorded and the injection molding machine checked at the specified time.

time2019/04/19

-

How to deal with the troubles we encountered when using the semi-automatic bottle blowing machine and share the precautions

time2019/05/15

-

Automatic bottle blowing machine temperature adjustment

When the automatic bottle blowing machine is processed, it is necessary to pay attention to some temperature control to ensure that a suitable plastic bottle is manufactured.time2019/06/03

-

SUZHOU COSTAR MACHINERY CO.,LIMITED is an authorised company located in Suzhou city,the capital of china`s plastics machinery industry .suzhou also has an extensive sales netword based in the world.products include injection molding machines mold,blowing machine and auxiliary equipment

time2020/07/27

-

As a guide, generally the injection machine should be selected so that molded product volume will become 30%

to 80% of the machine's injection volumetime2020/07/27

-

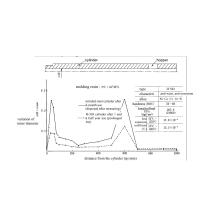

When molding NOVADURAN, resin temperature should be generally about 240℃~265℃. Liquidity will be better as the temperature rises, but extremely high temperature will accelerate heat degradation which will end up with physicality deterioration of the molded article.

time2020/07/27

-

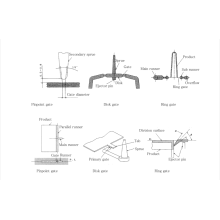

As for the injection molding machine, several types such as plunger type, plunger preplasticating type, screw preplasticating type and in-line screw type, etc. have been developed so far, but presently the in-line screw type injection molding machine

time2020/07/29

-

As for the molding of Iupilon / NOVAREX, either the hydraulic type or the toggle type is available.

time2020/07/29

-

The improvement of poor appearance of the moldings, the reduction of size unevenness between the molding shots, and the measures against sink marks, warpage and flash can be achieved by controlling the injection rate, holding pressure, screw rotation speed and back pressure with multistep program control at the time of injection

time2020/07/28

-

Defects to be encountered in molding of Iupilon / NOVAREX are almost similar to those of other plastic materials.

The defective causes and remedies of general grade and glass fiber reinforced gradetime2020/07/29

-

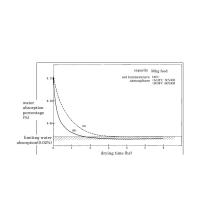

These results indicate that the degradation of the impact strength in addition to the generation of defective appearance is very large. Therefore, it is

important to use the dried pellets that the moisture content is lower than the above mentioned limit to have a good performance of Iupilon / NOVAREX.time2020/08/05

-

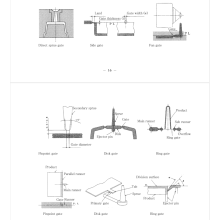

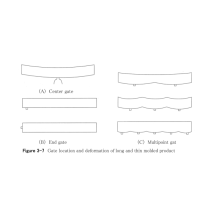

Used in the case of single- cavity, or when placing the gate directly to the base of the molded product.Residual strain tend to occur because the injection pressure will directly apply to the molded product, but its

mold construction is most simple.time2020/08/10

-

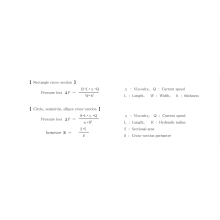

Practically, resin is a non Newtonian fluid with viscoelasticity, so viscosity will decrease if the shearing force get bigger and cross-section thickness and diameter get smaller. So the actual effect of pressure loss might be bit smaller than the formula above.

time2020/08/10

-

In the case of multi-cavity type, runner design will play an important role, because the dimension tend to vary widely. Family-cavity type, which molds the product with different cavity shapes simultaneously, is basically not recommended.

time2020/08/10

-

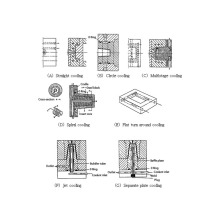

Design of the mold cooling circuit is very important because it will work as a heat exchanger that cools the resin when molding.

time2020/08/10

-

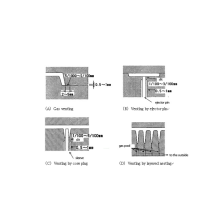

There are several ways to place a gas vent to the mold, but it can be classified broadly into the following three ways.

・ Gas venting from the divided face of the mold

・ Gas venting from the cavity and core part

・ Gas venting by other special waytime2020/08/10

-

Deformation and dimension change by warpage are often being a problem of PBT resin molded product.

Following factors are the cause of the warpage deformation, but actually it will happen when several factors

overlap intricately.time2020/08/10

-

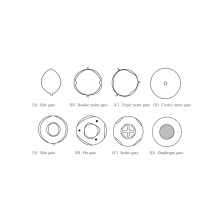

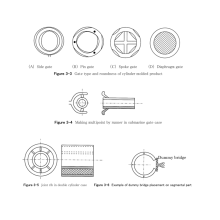

Generally, effect to the roundness by the gate type tend to be better in the following order.

Side gate < Pin gate(double points) < Pin gate (triple points) < Center sprue gatetime2020/08/10

-

Triple or quadruple-point gate is preferred, since it can directly get in from longitudinal direction. In the

case of the side gate or submarine gate, make the runner go around and prevent the core from falling over

by making it two to three pointstime2020/08/11

-

If the flow distance is long, there need to be a multipoint gate. In this case, attention against weld location is required. If the width of the molded product is large, setting up the multipoint pin gate on the centerline is good.

time2020/08/11

-

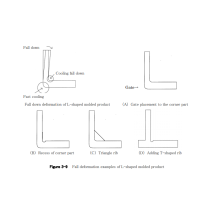

This shape will be affected a lot by the shape factor, so countermeasure by the molding condition is generally difficult. There is method that make difference in mold temperature, but it will accompany a hardship in facility aspect and management aspect.

time2020/08/11

-

(1) At the corner part, outside cooling will be faster than the inside, so this shape tend to deform towards the

inside direction.

(2) Remedying by placing the gate on the corner part is sometimes possible if it is GF reinforced grade.

(3) Lightening the corner inside part is effective. Make the recess part round, and do not make the sharp

corner.time2020/08/11

-

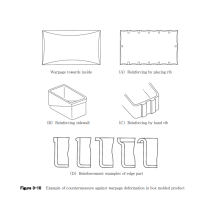

Generally, warpage towards inside tend to be bigger as the span get longer, and it tend to be bigger on the long side, compared to the short side. Remedying by placing a rib on the inside, or placing a triangle rib on the corner part, is possible.

time2020/08/11

-

As stated above, PBT will degrade in physicality by causing hydrolysis if heat history is received without enough drying, so the drying of fractured product need to be well considered when recycling.

time2020/08/11

-

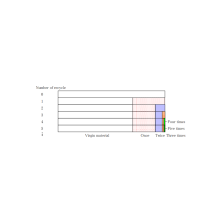

Proper recycled material mix rate depends on the recycled material quality, using grade, and product's demand characteristics, so cannot be completely defined. Therefore, decision of the limit of the recycled material ratio

should be made after sufficient check has been done.time2020/08/11

-

For example, if the actual recycled material ratio is 30%, substitution method can be made by testing once in recycled material ratio of 50%. However, recycling will be influenced greatly by pulverization shape and water control, so sufficient confirmation is required.

time2020/08/11

-

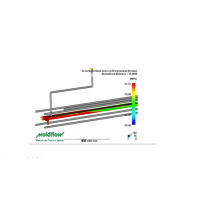

The mode flow analysis can assist the flow channel design, shorten the product development time and easily find the product potential problems, so as to improve the product quality and achieve the purpose of reducing the cost

time2020/09/17

-

The reason why injection mold is called the mother of industry is that it can produce plastic products of various shapes. In short, it can be created into various shapes and forms just like the silly putty played by children.But injection mold manufacturing is a fine job.There are a lot of details to look out for

time2020/09/17

-

The 13th China (Jinan) International Information Technology Expo and 2020 China (Jinan) High-end Digital Economy Summit will be held in Jinan International Convention and Exhibition Center.Shandong Shandong Huatian Software Co., LTD. (hereinafter referred to as Huatian Software), a well-known 3D intelligent manufacturing software enterprise in the industry, will appear at the expo site together with its r&d product software.

time2020/09/17

-

"Daming Machine" promotes the transformation and upgrading of new and old injection molding machines

Damien machine adhering to technology transfer in 60 years, cultivate professional after-sales service team, customer service department), within the team every member has 15 to 25 years of work experience, specialization Europe Japan's brand injection molding machine, two plate injection molding machine brands at home and abroad, domestic and foreign brands of direct pressure and injection molding machine ground type transformation and upgrading.

time2020/09/17

-

Optimistic injection molding machine, Apple industrial chain recovery, 5G base station to stimulate the demand for machine tools 1) continue to optimistic injection molding machine industry.Benefit from the epidemic, medical needs (forehead thermos, ventilators, etc)

time2020/09/17

-

Learned, 2021 the 13th Asia (nanjing) international exhibition on plastics and rubber industry on June 23 to 25, 2021 in nanjing international expo center, a total of more than 1000 enterprises both from home and abroad to come to the association, up to now, 80% of the pavilion booth has already been booked, many enterprises in order to play the 2021 battle of nanjing, the way they to exhibit in the pavilion early ready exhibitors

time2020/09/17

-

Plastic injection mold is very important in the whole mold industry.Now the proportion of plastic injection mold in the entire mold industry is about 30%, the proportion in the mold import and export as high as 50 ~ 70%.In recent years

time2020/09/18