Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

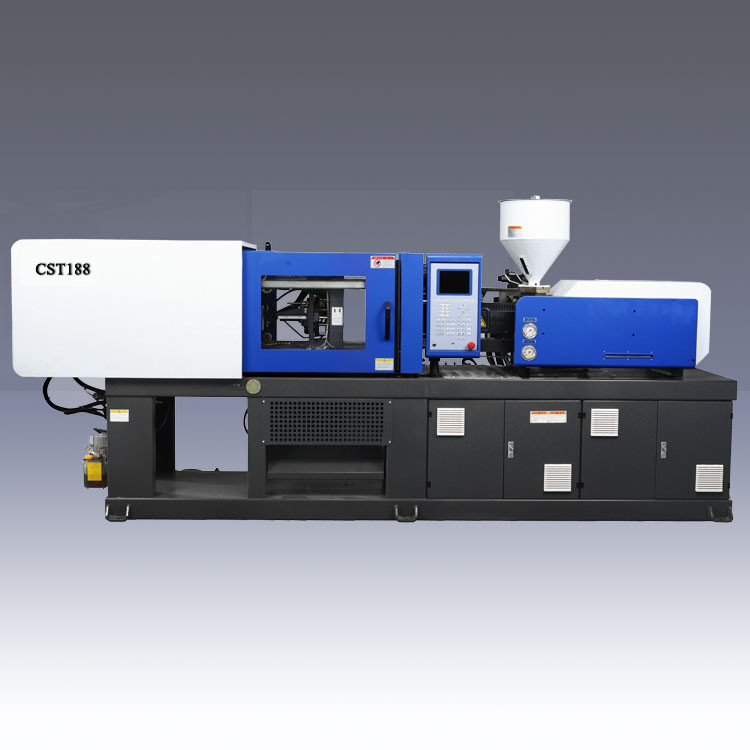

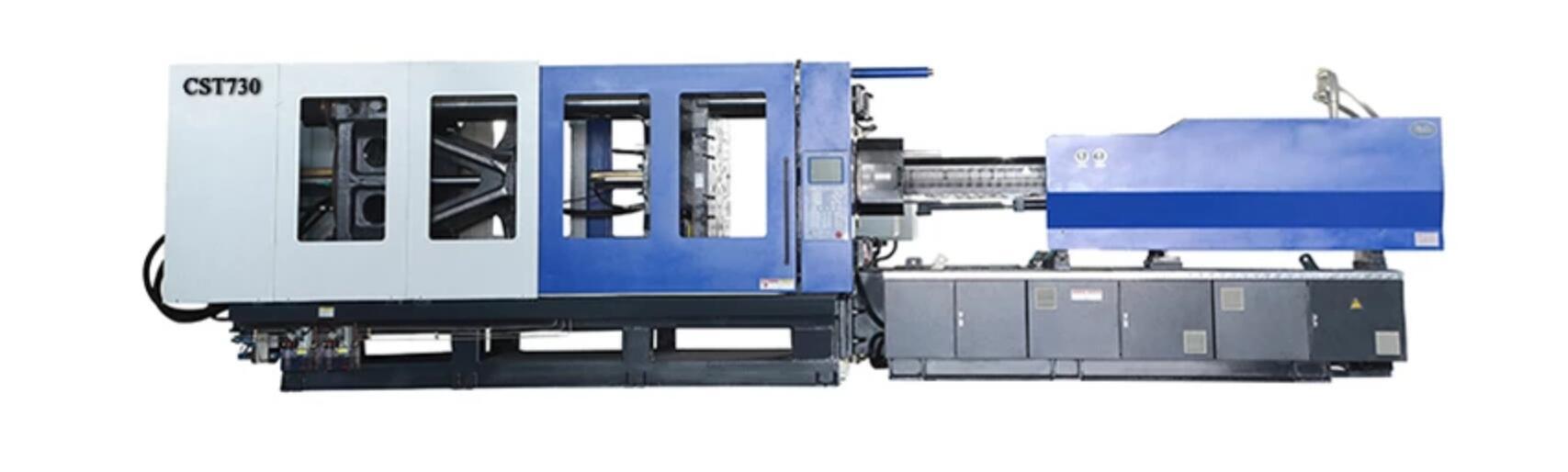

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

What breakthroughs do contemporary injection molding companies need?

time2018/11/04

- To become a powerful injection molding enterprise, you must purchase a large number of injection molding machines, manipulators and auxiliary machines, and introduce professional processing technology talents, which requires a lot of capital.

The injection molding industry is all-encompassing, from the simplest household items to home appliances, personal digital phones, automobiles, etc. all require injection molding. Plastic raw materials (even metals), various molding equipment auxiliary machines, molds, simulation software technology and processes are more and more, and more and more complicated, the time that a single machine master can get the entire workshop has gone, More and more diverse injection molding workshops are displayed in front of us. Gas-assisted, water-assisted molding, micro-foam molding, micro-injection molding, high-gloss seamless molding, in-mold decoration, multi-component molding, long glass fiber molding, liquid silicone, pearlescent spray-free molding and more new technologies Scale. To become a powerful injection molding enterprise, it is necessary to purchase a large number of injection molding machines, manipulators, and auxiliary machines, and to introduce professional process technology talents, which requires a lot of capital. The need for capital scale makes other companies need to cross a higher threshold when entering the industry. At the same time, high-end equipment companies (injection molding machines, etc.) serve mainly large companies, and the business scale of large companies is often large. This requires that injection molding enterprises, which are an important part of their supply chain, must have a large production scale, and only achieve production. Scale can effectively reduce procurement costs and production costs.

Technology. The injection molding industry needs strong technical strength, starting from product design, to mold flow analysis, mold making, trial mold, injection molding, production line assembly and secondary processing, surface treatment, etc., the steps are cumbersome, and these steps affect each other , Must cooperate in order to do well. Therefore, injection molding processing technology, quality control level and production management technology are very important and require a long time of practice and accumulation. At the same time, due to the rapid replacement of plastic products, injection molding companies need to continuously update and improve process technology, quality control and production management in many aspects.

Qualifications. Most of the high-quality customers in the injection molding industry are large manufacturers at home and abroad, and the standards for identifying qualified suppliers are relatively strict. In addition to meeting industry standards, they must also pass strict supplier qualification certification. Once the qualification of qualified suppliers is confirmed, in order to ensure product quality and maintain the stability of supply, manufacturers usually do not easily change the mold supply channel. This strict supplier qualification and stable customer relationship based on long-term cooperation have formed extremely strong qualification barriers for newly entered enterprises.

Management. Injection molding, a product needs to go through mold design, mold flow analysis, mold processing, trial mold, to actual mass production, secondary processing, assembly, any problem will cause quality problems, resulting in complaints and even returns for compensation. How to control such a long processing process, only through continuous practice and long-term accumulation, injection molding companies can continuously improve production management capabilities, establish a set of effective process operation standards, reduce corporate customer complaints, and eliminate quality problems. And this must be accumulated through a long period of time, which is not what newcomers can have in a short time.

Vision. The least important is also the most important. The author thinks that there is no such vision. If there is, then it is estimated that there is no time to write this article.