Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

-

To become a powerful injection molding enterprise, you must purchase a large number of injection molding machines, manipulators and auxiliary machines, and introduce professional processing technology talents, which requires a lot of capital.

time2018/11/04

-

The advantage of this system is that customers can access important information anytime, anywhere from anywhere in the world.

time2019/01/10

-

SUZHOU COSTAR MACHINERY CO.,LIMITED is an authorised company located in Suzhou city,the capital of china`s plastics machinery industry .suzhou also has an extensive sales netword based in the world.products include injection molding machines mold,blowing machine and auxiliary equipment

time2020/07/27

-

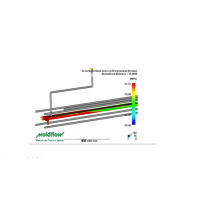

The mode flow analysis can assist the flow channel design, shorten the product development time and easily find the product potential problems, so as to improve the product quality and achieve the purpose of reducing the cost

time2020/09/17

-

Collection value of the most complete plastic mold knowledge

time2020/09/28

-

Designing plastic parts is a complex task that involves many factors and can meet a range of application requirements."How is the part used?""How does it fit into the rest of the assembly?""What kind of load does it carry?"In addition to functional and structural problems, machining problems also play an important role in the design of injection molded plastic parts.

time2020/11/04

-

The increase in accuracy and speed is consistent. The increase in speed will inevitably require an increase in accuracy; the increase in accuracy will inevitably lead to an increase in speed.

time2020/11/18

-

COSTARIs a collection of research and development, production, sales, as one of the plastic packaging machinery and plastic hollow products professional manufacturers.Main business scope: automatic plastic bottle blowing machine, PET bottle blowing machine, high barrier extruder and other series of bottle blowing machinery

time2020/11/24

-

Especially in the machinery manufacturing industry, the improvement of the performance of the product itself and the perfection of the working principle will enable the product itself to have more market profit share in the market.To this, we will talk about the working principle of the high quality injection molding machine.

time2020/11/27

-

Injection molding machine is also known as injection molding machine or injection molding machine. It is the main molding equipment that uses plastic molding molds to make plastic products of various shapes.

time2020/12/22

-

Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them.

time2020/12/24

-

Husky Husky Injection Molding Systems Ltd. provides molds, systems and services to customers in core markets.Design and manufacture various injection molding machines, hot runner, manipulator, mold and integrated systems.

time2021/01/19

-

Preform mould cooling is the very important issue, inefficient cooling will cause PET material crystallized under the high temperature, it will reduce the bottle blowing rate. Low quality cooling also will slow down the production speed. In order to realize the long time cooling effect, Sino Mould innovated with a very special design for most effective cooling solutions, also prevented water channel blocking due to the hard water.

time2021/01/27

-

When designing extruded plastic bottles, if the material is high-density polyethylene or polypropylene, the cross-section of the plastic bottle should be rectangular or elliptical. For low-density polyethylene or other flexible plastic bottles, the cross section It is better to use a circle

time2021/01/27

-

In the plastic processing industry, it is matched with plastic molding machines to give plastic products a complete configuration and precise size tools. Due to the wide variety of plastics and processing methods, and the complex and simple structures of plastic molding machines and plastic products, the types and structures of plastic molds are also diverse.

time2021/04/01