Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

What is the role of flow analysis in injection molds?

time2020/09/17

- The mode flow analysis can assist the flow channel design, shorten the product development time and easily find the product potential problems, so as to improve the product quality and achieve the purpose of reducing the cost

In the mold making process, it is very important and difficult to find the flow balance position in the runner design.In the past, it is often necessary to design the flow channel through past experience to achieve the purpose of flow balance, so it is necessary to find a solution through continuous practice, which will lead to prolonged product development time and increased costs.The mode flow analysis can assist the flow channel design, shorten the product development time and easily find the product potential problems, so as to improve the product quality and achieve the purpose of reducing the cost

1. Understand potential problems of injection molds

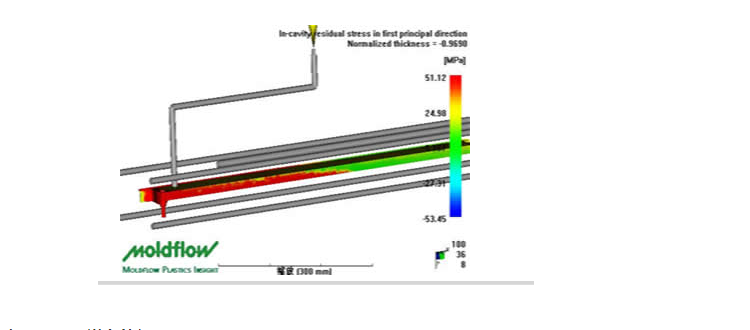

Mold flow analysis can predict the location and quantity of injection points from the basic alignment position, and save costs by improving part quality, eliminating downtime, and reducing cycle time and scrap rates.Flow simulations help refine product design by reducing or eliminating conditions that can cause gas defects, burns, indentations, voids, or excessive warping.This is done by optimizing factors such as gate size and position, runner balance in multi-cavity tools, material selection and process conditions.This technology can identify potential problems in injection molds before they occur.

2. Mold flow analysis will help to avoid potential problems in the mold

Competition in today's market requires suppliers to reduce costs while improving quality.Mold flow analysis enables mold manufacturers to reduce mold manufacturing costs, reduce lead time, and reduce component costs.

3. In addition to identifying and eliminating potential problems, die flow analysis helps optimize overall part and die design while preventing overengineering.

This can happen when too much effort is put into part/mold design.Designs often become more complex, using more plastic than is necessary.Modular flow analysis prevents unnecessary overengineering.Today's technology allows mold manufacturers to evaluate different cooling designs to reduce flow rates and optimize temperature distribution throughout the parts and molds, minimizing differential shrinkage, warping, and cycle times.