Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

Multistep program control of Injection Molding Machine

time2020/07/28

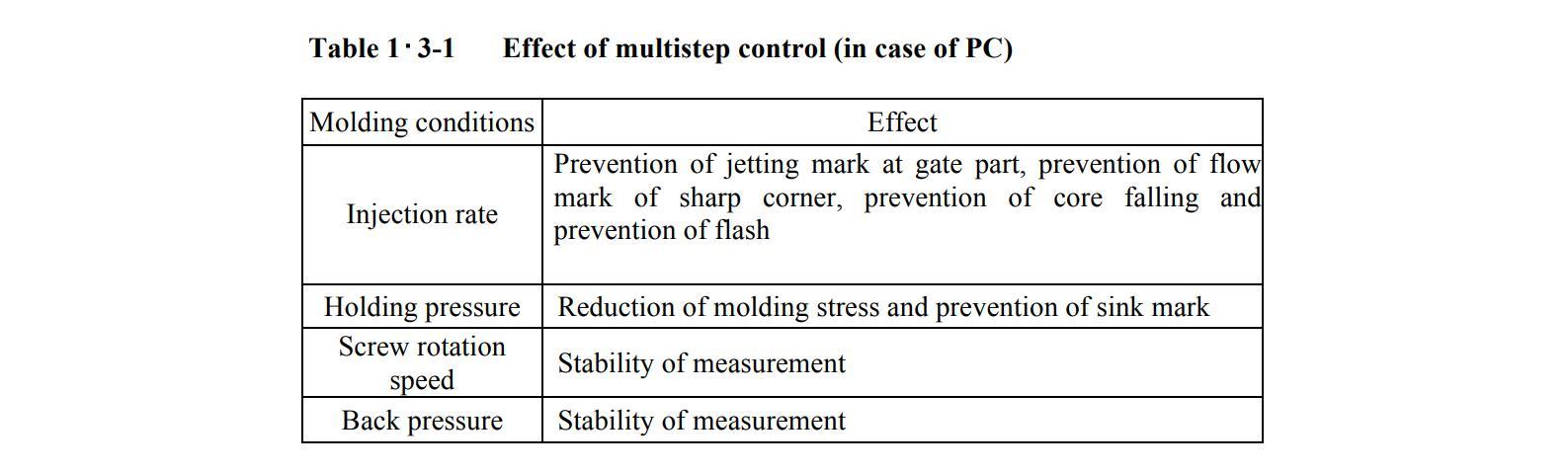

- The improvement of poor appearance of the moldings, the reduction of size unevenness between the molding shots, and the measures against sink marks, warpage and flash can be achieved by controlling the injection rate, holding pressure, screw rotation speed and back pressure with multistep program control at the time of injection

The improvement of poor appearance of the moldings, the reduction of size unevenness between the molding shots, and the measures against sink marks, warpage and flash can be achieved by controlling the injection rate, holding pressure, screw rotation speed and back pressure with multistep program control at the time of injection

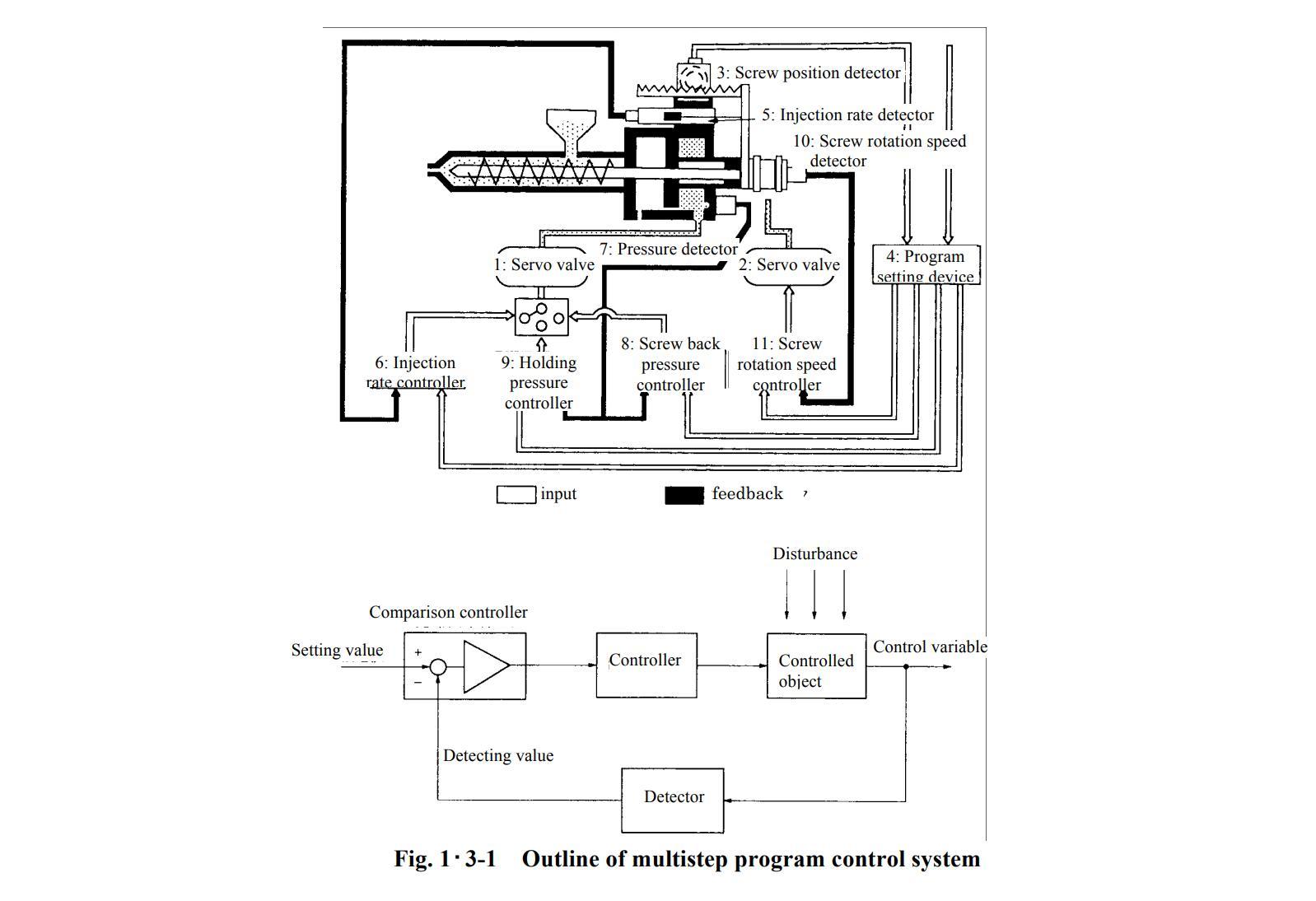

The effect of multistep program control in PC and its control system are indicated in Fig. 1・3-1. The outline is

introduced below. 3)

〈Control of the injection rate〉

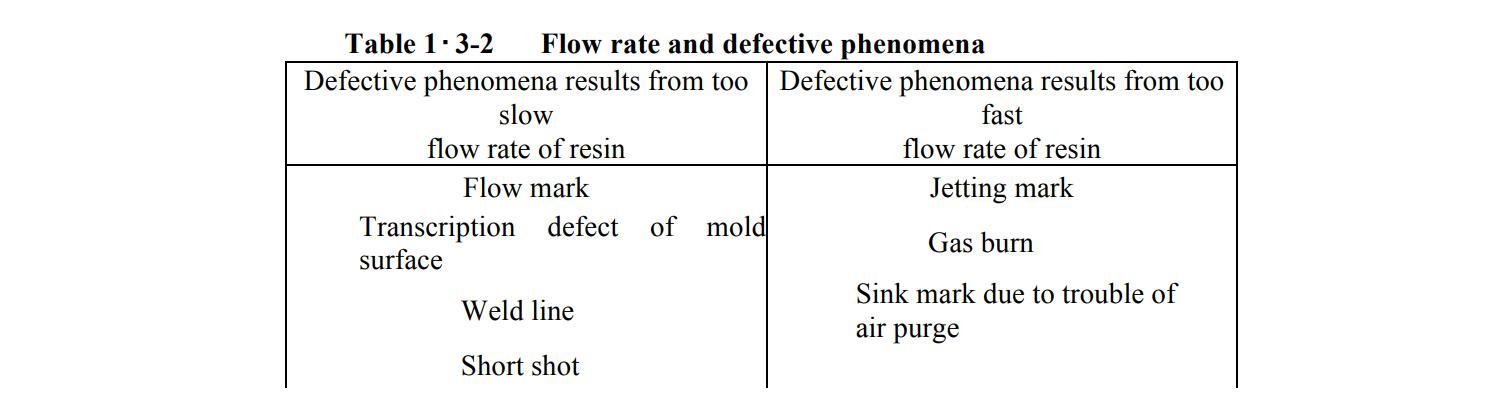

Since the poor appearance is resulted from the change of rate of the flow front, the measures can be done by controlling

the injection rate. The relationship between the flow rate and the defective phenomena is summarized in Table 1・3-2. It

can be understood that the injection rate should be set to an appropriate range because there is a problem even if the flow

rate is too fast or too slow.

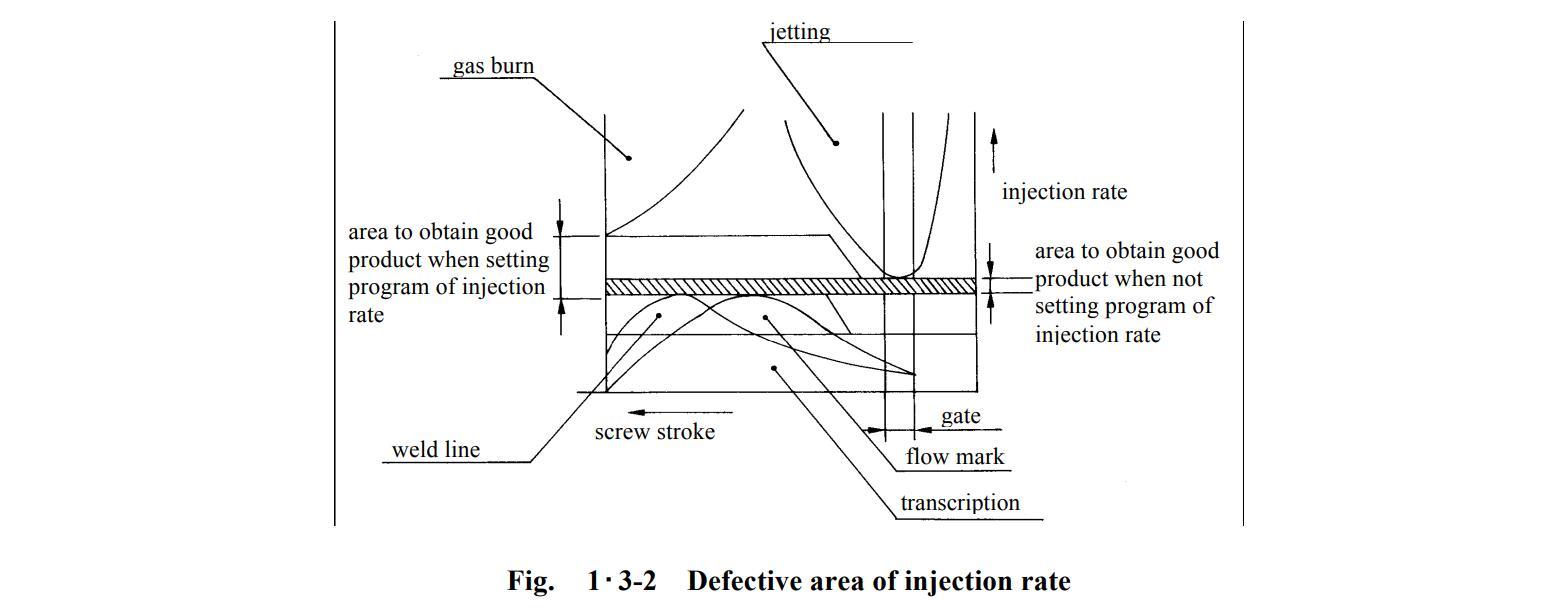

Fig. 1 3-2 indicates an example of a measure to avoid the area of various defective phenomena by controlling the

injection rate with multistep program control.

It is understood that the setting range of the injection rate to have a product of good quality is narrow (shaded part) in

case of general molding.

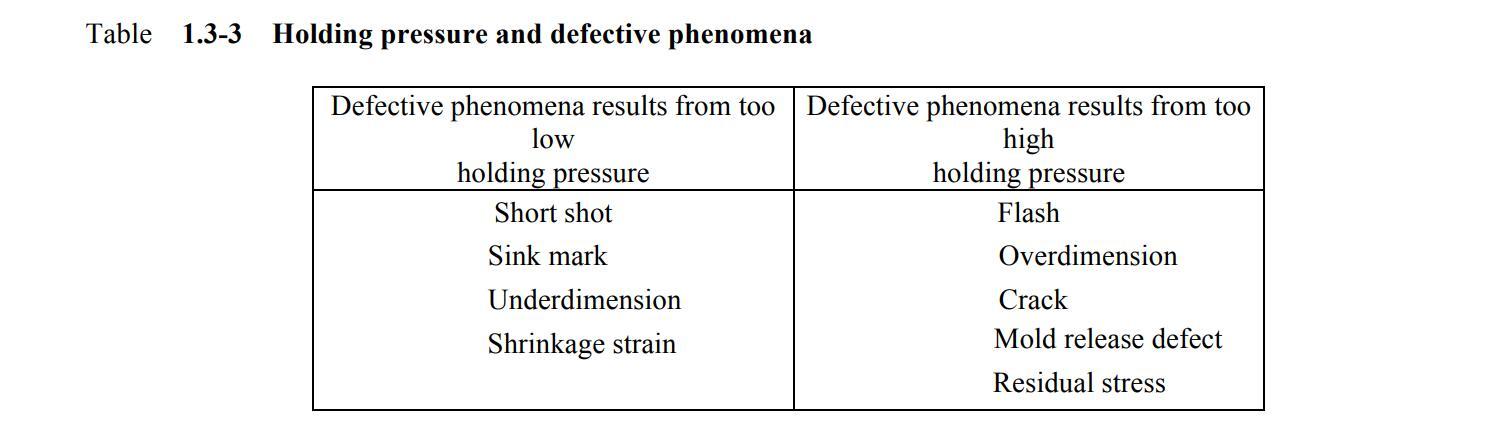

〈Control of the holding pressure〉

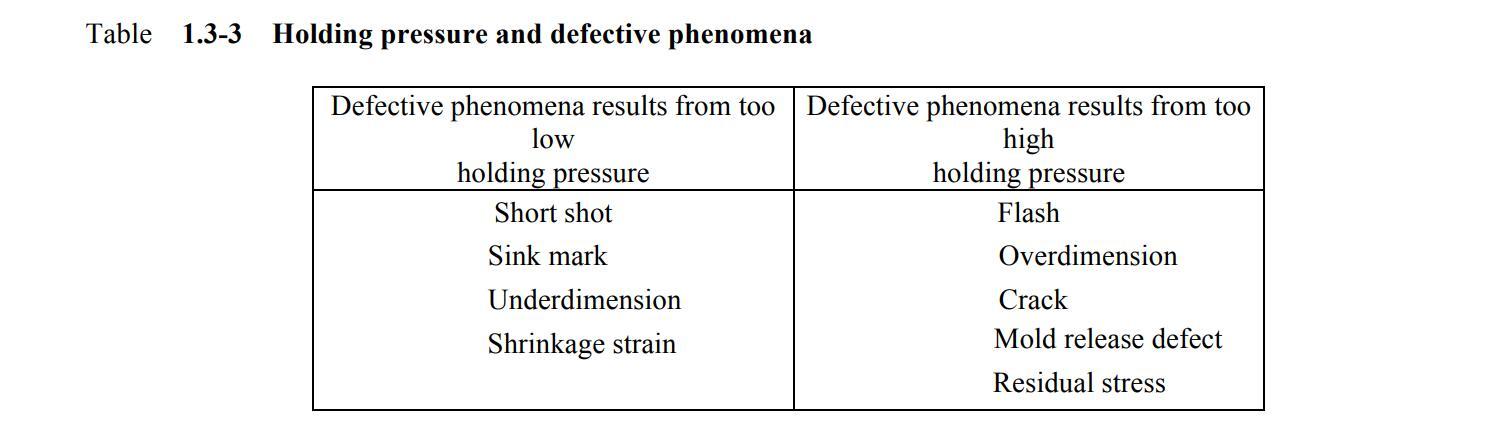

The defective phenomena such as sink marks, warpage and flash are related to the holding pressure.

The measure against these phenomena becomes possible by controlling the holding pressure.

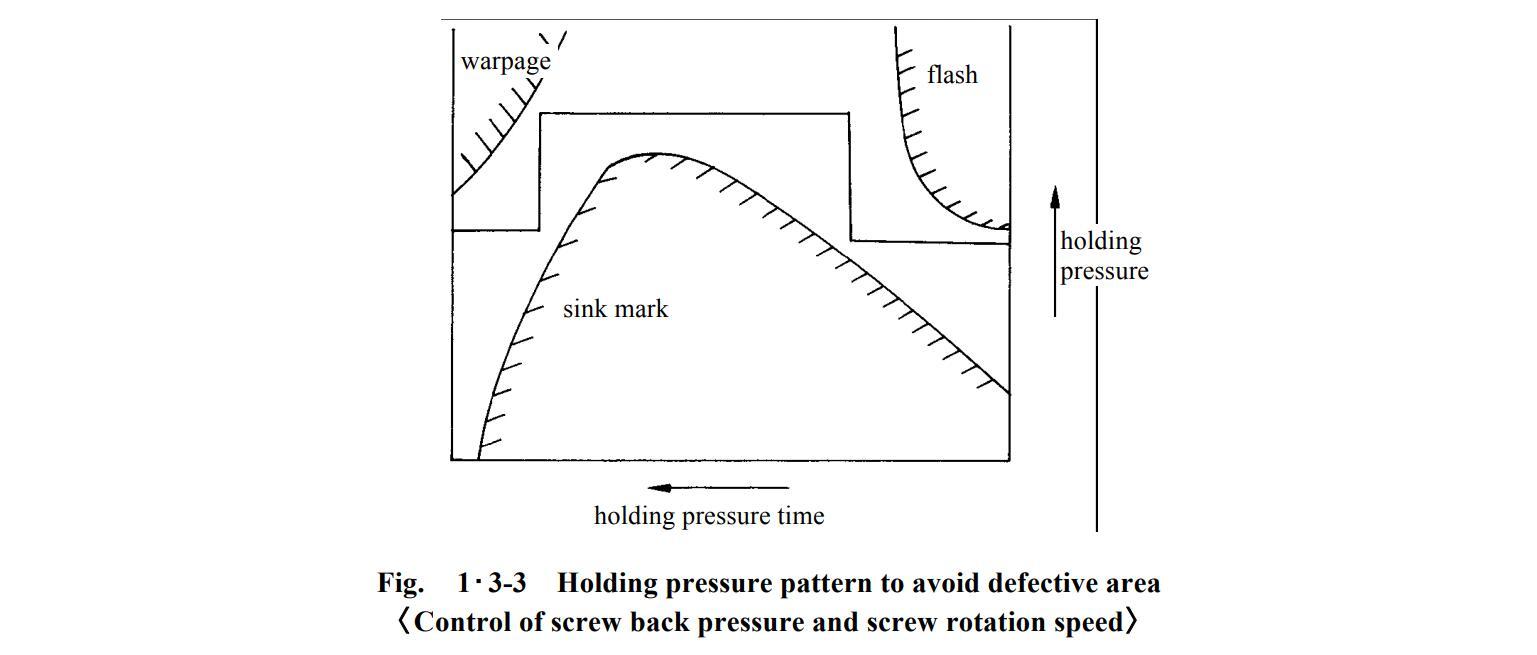

The relationship between the defective phenomena such as sink marks, warpage and flash and the holding pressure is

summarized in Table 1・3-3. Figure 1・3-3 indicates the pattern of the holding pressure program which was obtained to

avoid the defective phenomenon area.

The stability of measurement (plasticization) is related to screw back pressure and screw rotation speed.

It is possible to improve the accuracy of uneven repeated measurement by controlling these factors.

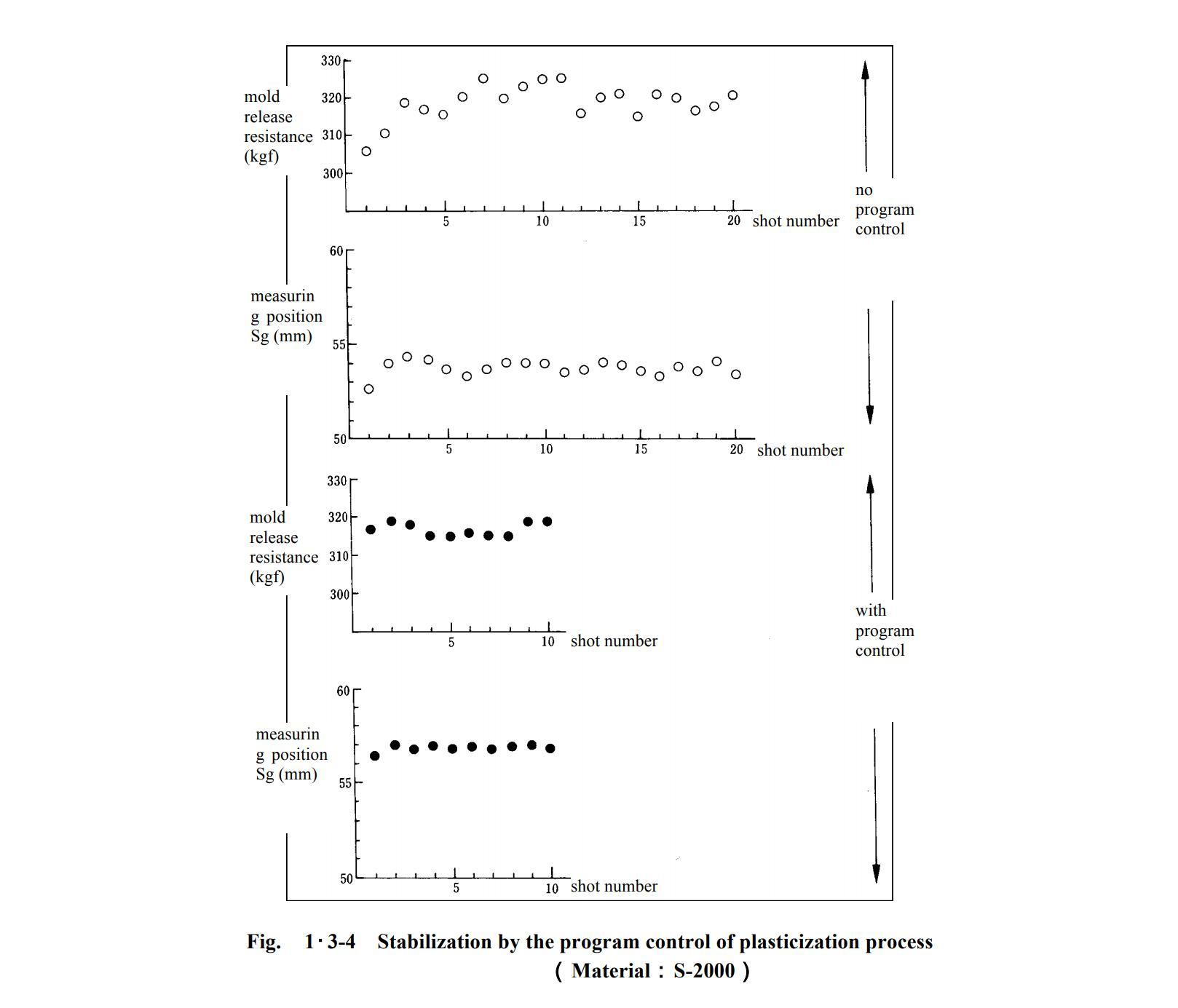

Fig. 1・3-4 indicates the result of comparing the effects of the multistep program control of screw back pressure and

screw rotation speed about the measurement position or mold release resistance4).

From this figure, it is thought that the unevenness of the measurement position, mold release resistance was decreased

by the multistep program control.