Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

NOVADURAN can be recycled

time2020/08/11

- As stated above, PBT will degrade in physicality by causing hydrolysis if heat history is received without enough drying, so the drying of fractured product need to be well considered when recycling.

Points of recycling

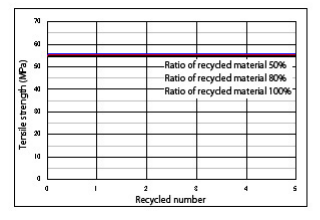

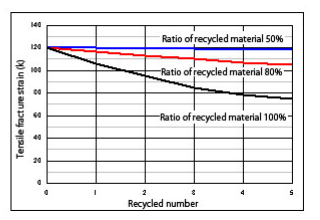

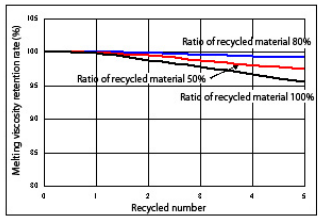

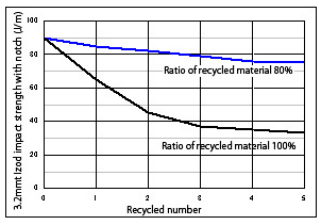

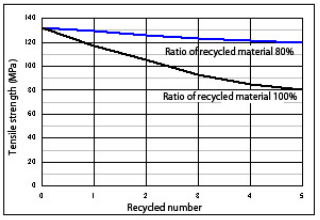

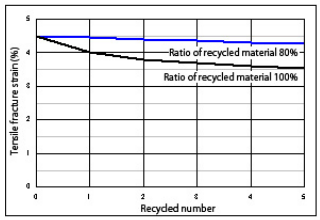

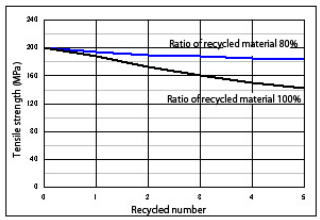

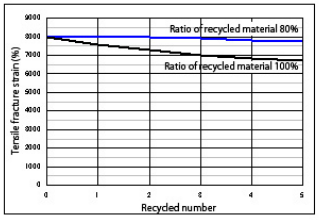

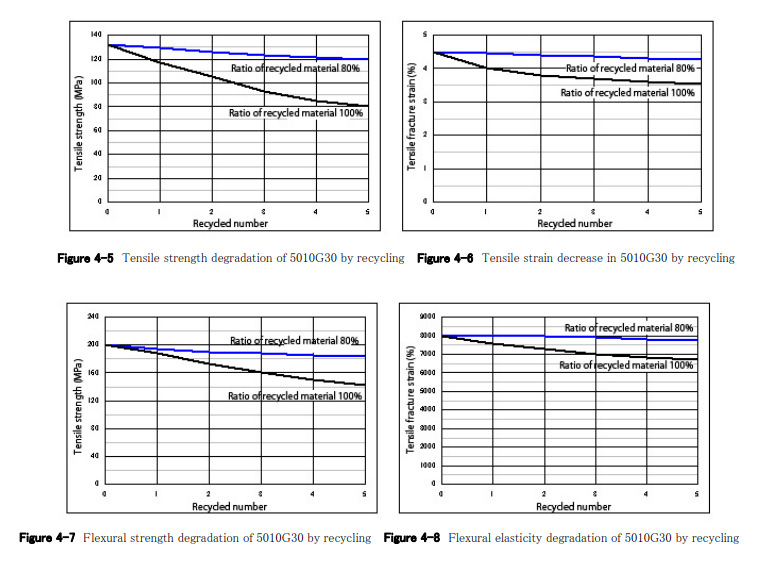

NOVADURAN can be recycled, but it might cause trouble if the direction is not good. As stated above, PBT

will degrade in physicality by causing hydrolysis if heat history is received without enough drying, so the drying of

fractured product need to be well considered when recycling. Also, in the case of GF reinforced grade, GF

fracture will occur when pulverizing, and degrade in strength when recycling tend to be bigger than the

unreinforced grade. Figure 4-1 to 4-8 indicate examples of physicality change when recycled NOVADURAN is

used.

Recycled material ratio of about 30% is possible in general NOVADURAN molding, if the direction is good

enough. If recycled material ratio goes over 30% or the water control of the recycled material is not good,

problem such as crack might occur. If the molded product is thin or have complex structure, often the mold

temperature will be high and large molding machine will be used, physicality degradation tend to occur when

molding, even if the drying is enough.