Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

-

The so-called standard die frame is generally composed of the fixed die base plate of the upper die, the fixed mold plate, the moving mold supporting plate, the pad block, the moving mold base plate, the push rod fixed plate, the push plate, the guide column, the guide sleeve and the reset rod, etc

time2020/09/21

-

The trend of change: South China Sea force supports a trillion extensive household industry cluster

time2020/09/24

-

These daily necessities molds are made by the injection molding process, but before injection molding, we need to use this tool to make the mold shells for daily necessities-the mold shell molds commonly used for daily necessities.

time2020/09/27

-

From a novice in the face of machine mistakes to winning in the World Championship, to the present coach leading the team members to compete in the World Championship, the Guangdong World Championship champion brothers Zhang Zhikun and Zhang Zhibin, you chase me and encourage each other on the way to pursue your dreams.

time2020/09/27

-

The study aggregated key data on the competitive landscape in multiple regions where the vertical market and business successfully established a location.

time2020/09/27

-

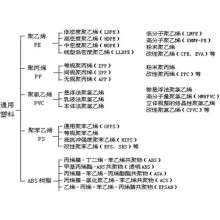

Collection value of the most complete plastic mold knowledge

time2020/09/28

-

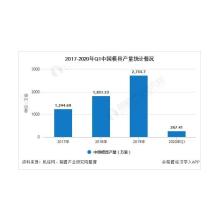

In 2020, China's plastic mold industry market status and development trend analysis design and manufacturing intelligent, green development

time2020/09/29

-

The report discusses a number of critical industry aspects that will have a profound impact on the global electric injection molding machine market, including extensive research on competitive advantages, the latest developments, the industry environment by region, contemporary and emerging market trends, leading market competitors and current trends.The consumer.

time2020/10/09

-

Still need to explain a point is that the domestic vertical injection molding machine said here is to point to the big manufacturers, not the products of small manufacturers.

time2020/10/10

-

Overflow, also known as flash and overflow, usually occurs at the parting and closing positions of molds.For example, the parting surface of the mold, the slot of the insert and the hole of the pin

time2020/10/10

-

With the development of automobile industry, the roughness performance of automobile noise, vibration and sound vibration is highly valued.A sealing strip should be added to the gap between the front door's B-pillar window frame and the back door's B-pillar window frame to improve the sealing surface's resistance to foreign elements entering the cabin.The sealing strip is composed of two kinds of rubber with different materials.

time2020/10/12

-

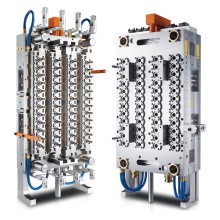

What are the advantages of multi-cavity mold?In order to increase the productivity and reduce the pouring loss of the passage, multi - cavity molds can be used to finish many same or different products simultaneously within one mold

time2020/10/12

-

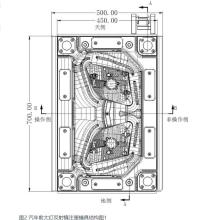

Automobile headlight reflector (also known as reflector) is a part of automobile headlight lighting system that has the function of reflection to avoid direct light. It is located inside the lens and decorative frame and assembled with the lens. Through the lens, the reflector can be seen from the outside of the vehicle light.Plastic parts for appearance, surface aluminum plating, belongs to the high - light electroplating parts, the surface has a large area of decorative surface

time2020/10/13

-

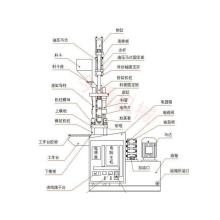

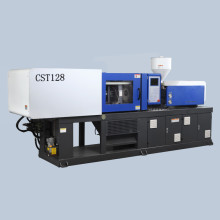

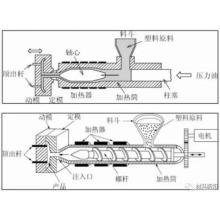

It is the main molding equipment for making thermoplastic or thermosetting plastics into various shapes of plastic products through plastic molding molds. Including vertical, horizontal, and all-electric. The injection molding machine can heat the plastic and apply high pressure to the molten plastic to inject it to fill the mold cavity

time2020/10/22

-

Injection molding machine is also called injection molding machine or injection machine. It is the main molding equipment for making thermoplastic or thermosetting plastics into various shapes of plastic products through plastic molding molds.

time2020/10/22

-

Material for injection mold (plastic mold steel) is required to have sufficient strength, toughness, heat resistance, wear resistance, and good corrosion resistance, heat treatment hardness must be greater than 42-48HRC, cavity working surface needs to keep the surface roughness unchanged for a long time.Commonly used materials are 45, Tl0, TlOA, 9Mn2V, 3Cr2W8, etc.Therefore its electric discharge machining process basic rules are as follows.

time2020/10/22

-

Injection molding is a manufacturing process for mass production of parts.It is most commonly used for mass production of the same parts, usually on a scale of tens of thousands or even millions of times.

time2020/10/24

-

Polycolor injection is, as the name suggests, realized with more than two kinds of plastic injection for a part.The broad multi-color injection molding includes over Molding, which is achieved by two injection molding with an ordinary molding machine.

time2020/10/24

-

Injection molding is an engineering technique that involves turning plastics into useful products that retain their original properties.The important technological conditions of injection molding are the temperature, pressure and corresponding action time of plasticizing flow and cooling.

time2020/10/24

-

The lock mode is the most prone to vibration, and the life of the machine for vibration and stability have great influence, when adjusting the lock mode so please note the following items: mould opening slow speed is the speed of mold start, so speed under medium

time2020/10/24

-

Designing plastic parts is a complex task that involves many factors and can meet a range of application requirements."How is the part used?""How does it fit into the rest of the assembly?""What kind of load does it carry?"In addition to functional and structural problems, machining problems also play an important role in the design of injection molded plastic parts.

time2020/11/04

-

Professional manufacturer of asphalt machines. Our sales and R&D team have over 10 years’ experience to focus on asphalt distributor, synchronous pavement surface vehicles and other road machinery and equipment. Based on innovation

time2020/11/05

-

E-mac130 manufactures the brakes on Harting's Han-Quicklock connector, using a 6-die cavity.It is understood that - the connector housing usually installed up to 100 brakes, and according to the connector type varies, they will allow the stranded wire to achieve fast, simple connection.

time2020/11/07

-

The increase in accuracy and speed is consistent. The increase in speed will inevitably require an increase in accuracy; the increase in accuracy will inevitably lead to an increase in speed.

time2020/11/18

-

COSTARIs a collection of research and development, production, sales, as one of the plastic packaging machinery and plastic hollow products professional manufacturers.Main business scope: automatic plastic bottle blowing machine, PET bottle blowing machine, high barrier extruder and other series of bottle blowing machinery

time2020/11/24

-

The Report Titled, Medical Plastic Injection Molding Market Research: Global Status & Forecast by Geography, Type & Application (2020-2026) has been recently published. The Medical Plastic Injection Molding Market has been garnering remarkable momentum in recent years

time2020/11/25

-

Bottle blowing machine is a kind of equipment to make plastic particles into hollow containers by blow molding process. At present, there are two relatively common kinds. One is a hollow extrusion and blowing machine that USES PP and PE to form once; the other is a two-step bottle blowing machine that USES PET, PC or PP to form twice.

time2020/11/25

-

Especially in the machinery manufacturing industry, the improvement of the performance of the product itself and the perfection of the working principle will enable the product itself to have more market profit share in the market.To this, we will talk about the working principle of the high quality injection molding machine.

time2020/11/27

-

According to the prospectus, according to the "China Plastics Machinery Industry Statistical Yearbook 2019" data, the market size of my country's injection molding machine industry from 2017 to 2019 was 21.875 billion yuan, 22.686 billion yuan and 23.302 billion yuan, and the company's domestic sales revenue of injection molding machines was 4.15

time2020/12/18

-

Multi-material injection molding (Multi-material Injection Molding) technology has been developed for many years and is widely used in the automotive industry, electronics, medical and other fields, and brings extraordinary economic benefits. It is a technology with development potential.

time2020/12/03

-

Injection molding machine is also known as injection molding machine or injection molding machine. It is the main molding equipment that uses plastic molding molds to make plastic products of various shapes.

time2020/12/22

-

Injection molding is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them.

time2020/12/24

-

This laser marking machine market research report provides comprehensive data that can enhance the understanding, scope and application of the report.

time2021/01/09

-

Husky Husky Injection Molding Systems Ltd. provides molds, systems and services to customers in core markets.Design and manufacture various injection molding machines, hot runner, manipulator, mold and integrated systems.

time2021/01/19

-

Preform mould cooling is the very important issue, inefficient cooling will cause PET material crystallized under the high temperature, it will reduce the bottle blowing rate. Low quality cooling also will slow down the production speed. In order to realize the long time cooling effect, Sino Mould innovated with a very special design for most effective cooling solutions, also prevented water channel blocking due to the hard water.

time2021/01/27

-

When designing extruded plastic bottles, if the material is high-density polyethylene or polypropylene, the cross-section of the plastic bottle should be rectangular or elliptical. For low-density polyethylene or other flexible plastic bottles, the cross section It is better to use a circle

time2021/01/27

-

When it comes to plastic products used for food, beverage, and medicine, quality is critical. This is why leading PET preform manufacturers like Chemco rely heavily on cleanroom facilities, specifically the Class 10,000 standard.

time2021/02/02

-

India initiates anti-dumping investigation against Chinese plastic processing machinery

time2021/02/19

-

36 Krypton first release to realize the industrialization of 3D printing technology in the mold industry

time2021/02/19

-

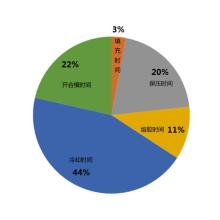

For an injection molded product, its molding cycle is affected by many factors, such as: filling time, holding time, sol time, mold opening and closing time, but the longest and most important one is cooling. time.

time2021/03/01