Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

Gate selection should be made considering efficiency, and moldability.

time2020/08/10

- Used in the case of single- cavity, or when placing the gate directly to the base of the molded product.Residual strain tend to occur because the injection pressure will directly apply to the molded product, but its

mold construction is most simple.

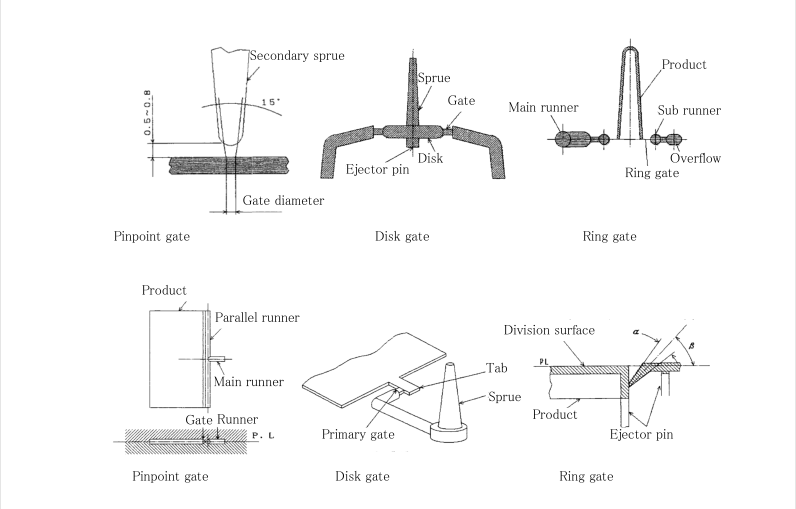

Gate selection should be made considering molded product shape, number, performance, appearance,economic efficiency, and moldability. There are many types of gates, and Figure 2-11 indicates structure of each gate.

Figure 2-11 Gate type and structur

(1) Direct sprue gate

Used in the case of single- cavity, or when placing the gate directly to the base of the molded product. Residual strain tend to occur because the injection pressure will directly apply to the molded product, but its mold construction is most simple.

(2) Side gate

This type is most generally adopted, and used well in multi-cavity mold. Its shape is rectangle or semicircle,and placed at side of the molded product.

(3) Fan gate

Its structure is similar to the side gate, but gate width is bigger and fan-shaped. Used in large size molde product.

(4) Pinpoint gate

Diameter of the pinpoint gate is 0.5mm to 2mm, and as an advantage, it does not need any finishing. Gate seal is fast and pressure that generates residual strain will not apply to the molded product. If the gate cross-sectional area is small, flow distance will decrease and flow marks tend to occur around the gate.

(5) Disk gate

This gate is used to prevent eccentricity and weld when molding disk or cylinder shaped one. However, there is a disadvantage that the finishing of the gate part is difficult.

(6) Ring gate

Used like the disk gate. Ring part must get filled first and then the cylinder part, otherwise the weld will occur.

(7) Film gate

This type will be applied to the plate shaped molded product. This type is effective to prevent deformation by suppressing residual strain.

(8) Tab gate

This is a method that set up a tab on the side of the molded product, and place a gate there. Normally, the gate and the tab should be placed at a right angle. Gate seal will happen on the gate part, so suppressing residual strain and flow marks inside the tab is possible.

(9) Submarine gate

There is a runner part on the parting line surface, but the gate reach the side of the molded product through fixed template or moving template from the runner part. When releasing the mold after mold opening, the gate will automatically get cut.