Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

Model calculation on repetitious recycling

time2020/08/11

- For example, if the actual recycled material ratio is 30%, substitution method can be made by testing once in recycled material ratio of 50%. However, recycling will be influenced greatly by pulverization shape and water control, so sufficient confirmation is required.

Model calculation on repetitious recycling

As a reference, model calculation of recycled material ratio and physicality degradation on repetitious

recycling is indicated. If the recycled material mix rate is a constant value "r", recycled material ratio on

repetitious recycling will be as following.

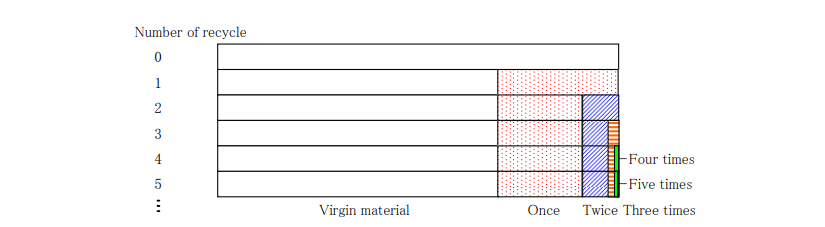

Number of recycle Virgin material Once recycled material Twice recycled material Three times

recycled material Four times recycled material Five times recycled material ...

0 1

1 1-r r

2 1-r r(1-r) r2

3 1-r r(1-r) r2(1-r) r3

4 1-r r(1-r) r2(1-r) r3

(1-r) r4

5 1-r r(1-r) r2(1-r) r3

(1-r) r4

(1-r) r5

Ex) If r=0.3(30% recycled), image will be like Figure 4-9

Figure 4-9 Recycled material mixed image when 30% recycled

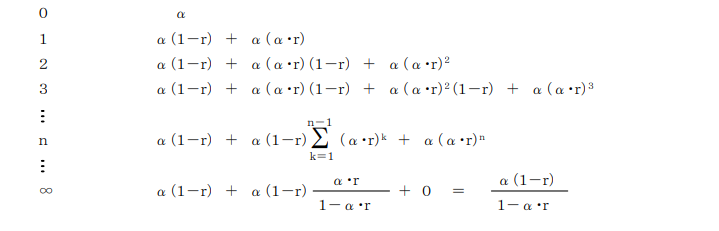

Furthermore, considering the physicality degradation by heat history from one molding, and replacing that

physicality retention rate with "α", physicality retention rate in each recycled time will be shown as below.

Number of recycle Physicality retention rate

Figure 4-10 indicates relation between number of recycle and physicality retention rate in the case that

recycled material ratio r=0.1,0.3,0.5, and physicality retention rate α=0.98,0.95. In each case,

physicality retention rate will be close to attainable retention rate if the recycling have been done about five

times, so recycling should be considered about five times in recycling discussion of the product. If the recycling

material ratio is too high, attainable retention rate will decrease, and recycling number tend to increase to get

close to the attainable retention rate and get stabilized (Figure 4-11). Generally, recycled material ratio should

be below 30%.

If recycling number cannot be increased, consideration can be made on recycled material ratio thinking about

attainable retention rate. For example, if the actual recycled material ratio is 30%, substitution method can be

made by testing once in recycled material ratio of 50%. However, recycling will be influenced greatly by

pulverization shape and water control, so sufficient confirmation is required.