Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

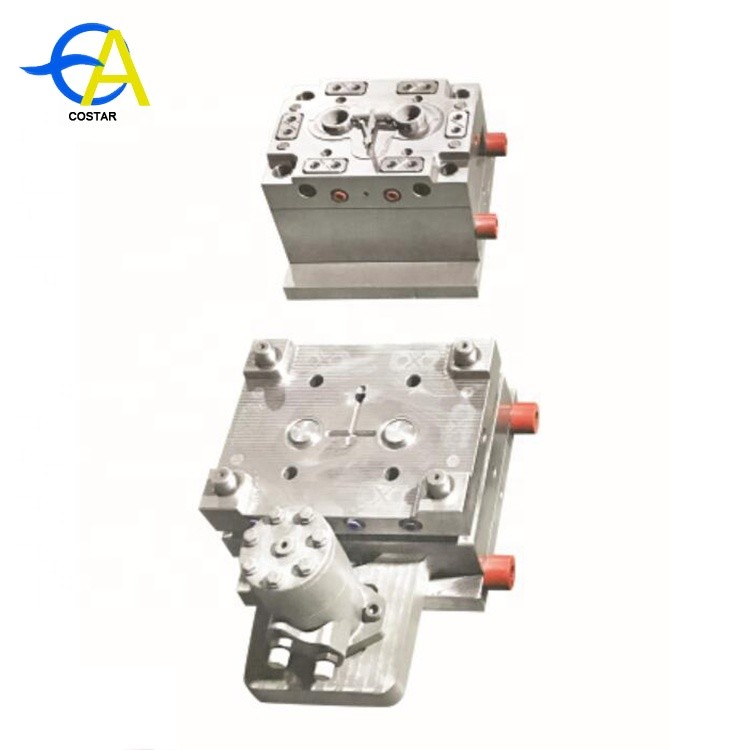

Caps mould manufacturers 12 cavity bottle cap injection moulding machine plastic mould

- group name

- All kinds of injection plastic molds

- Min Order

- 1 set

- brand name

- COSTAR

- model

- OEM

- Nearest port for product export

- ningbo, shanghai

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Wed, 11 Nov 2020 12:01:04 GMT

Paramtents

Place of Origin Zhejiang, China

Product Industrial products

Mould material P20/718/738/NAK80/S136/2738/2316

Package Wooden Box

Delivery Time 45-60days

Quality High Level

Brand Name COSTAR

Packging & Delivery

-

Min Order1 set

Briefing

Detailed

Place of Origin: | Jiangsu, China | Cavity/Core Material: | 718H, P20, NAK80, 2316, 2738, 2344 |

Product Material: | ABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, PA, PBT, PEI, etc., Steel | Longevity: | Available SHOTS will depend on the steel material you choose |

Runner System: | Hot runner, Cold runner | Cavity: | Single cavity, multi cavities by requested |

Finish: | Corrosion word, Mirror finish, Brushed | Base: | LKM or by requested |

Mould standard: | HASCO, DME, MISUMI, or by requested etc. | Software: | CAD, Pro-E, UG, etc |

Main Technique: | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc. | Shaping Mode: | Plastic Injection Mould |

Product: | Household Product |

Machine Feature:

1 Enhanced clamping mechanism to meet requirements for efficient production.

2 Excellent clamping features with optimized linkage mechanism to have faster and smooth operation.

3 Professional plasticizing unit is applicable for production of various raw materials, and to improve plasticize performance significantly.

4 Excellent injection performance with twin-cylinder injection mode, have more reliable and stable performance.

5 Professional platen optimization, the platen after finite element analysis and optimization has high rigidity and strength.

6 Centralized lubrication system with reliable protective configuration, quantitative distribution and centered lubrication, provide more professional lubrication protection and extend mechanical life.

7 New frame type structure, simple and clean appearance, with more reasonable stress on machine body and high rigidity.