Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

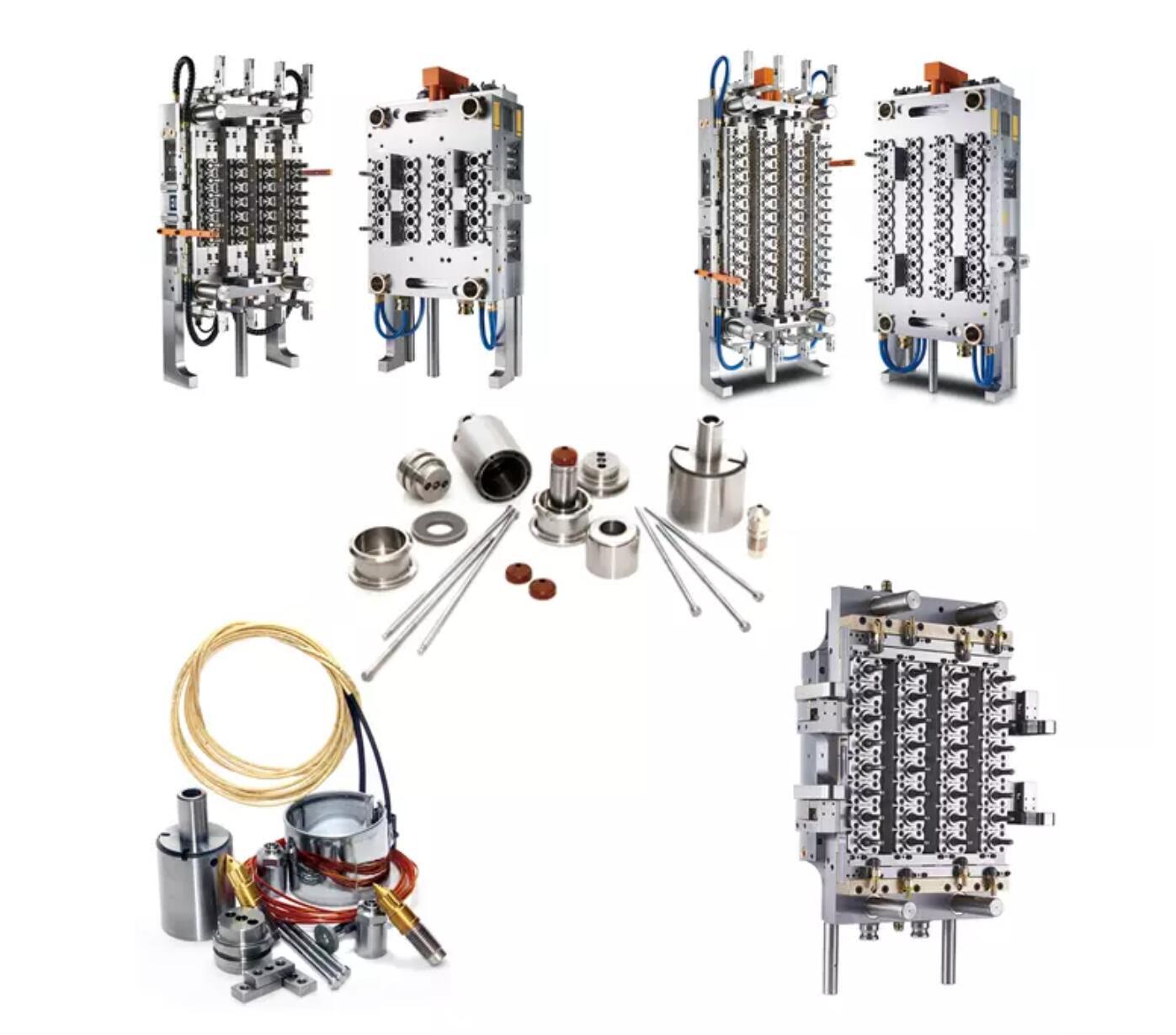

hot runner water bottle preform mould multi cavity plastic injection pet preform mold

- group name

- Preformed preform injection mold

- Min Order

- 1 piece

- brand name

- COSTAR

- model

- OEM

- Nearest port for product export

- ningbo, shanghai

- Delivery clauses under the trade mode

- FOB

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Wed, 27 Jan 2021 15:01:03 GMT

Paramtents

Cavity/Core Material 718H, P20, NAK80, 2316, 2738, 2344

Product Material ABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, PA,

Base LKM or by requested

Runner System Hot runner, Cold runner

Packging & Delivery

-

Min Order1 piece

Briefing

A hot runner water bottle preform mold multi-cavity injection plastic pet bottle preform mold sold at ex-factory price

Detailed

Overview

Place of Origin: |

Jiangsu, China |

Cavity/Core Material: |

718H, P20, NAK80, 2316, 2738, 2344 |

Product Material: |

ABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, PA, PBT, PEI, etc., Steel |

Longevity: |

Available SHOTS will depend on the steel material you choose |

Runner System: |

Hot runner, Cold runner |

Cavity: |

Single cavity, multi cavities by requested |

Finish: |

Corrosion word, Mirror finish, Brushed |

Base: |

LKM or by requested |

Mould standard: | HASCO, DME, MISUMI, or by requested etc. | Software: | CAD, Pro-E, UG, etc |

Main Technique: | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc. | Shaping Mode: | Plastic Injection Mould |

Product: | Household Product |

Supply Ability

Supply Ability:400 Set/Sets per Month pet preform mold

Packaging & Delivery

Packaging Details:Factory price hot runner water bottle preform mould multi cavity plastic injection pet preform mold

Wooden case, or by request

Port:Shanghai Port/Ningbo Port

Product Display

Machine Feature:

1 Enhanced clamping mechanism to meet requirements for efficient production.

2 Excellent clamping features with optimized linkage mechanism to have faster and smooth operation.

3 Professional plasticizing unit is applicable for production of various raw materials, and to improve plasticize performance significantly.

4 Excellent injection performance with twin-cylinder injection mode, have more reliable and stable performance.

5 Professional platen optimization, the platen after finite element analysis and optimization has high rigidity and strength.

6 Centralized lubrication system with reliable protective configuration, quantitative distribution and centered lubrication, provide more professional lubrication protection and extend mechanical life.

7 New frame type structure, simple and clean appearance, with more reasonable stress on machine body and high rigidity.