Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

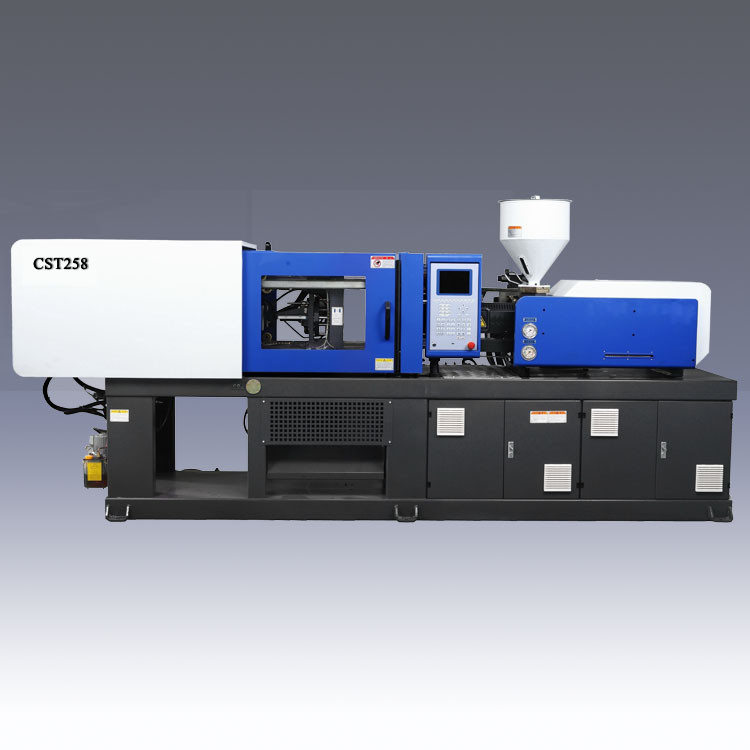

Composition and working principle of injection molding machine

time2021/03/20

- The injection molding machine is a special equipment that combines the thermal processing characteristics of plastics and the principle of metal melting and die casting. The first plunger injection molding machine, it was not until the end of the 1940s that a pre-plasticized screw injection molding machine was developed.

The injection molding machine is a special equipment that combines the thermal processing characteristics of plastics and the principle of metal melting and die casting. The first plunger injection molding machine, it was not until the end of the 1940s that a pre-plasticized screw injection molding machine was developed. Since then, the focus of development has been mainly around the pre-plasticized screw injection molding machine, and advanced forms such as twin screw and exhaust type have appeared in the future.

In 1980, France produced the world's largest screw injection molding machine with a single injection capacity of 170kg. From the 1980s to recent years, the development of injection molding machines was mainly concentrated in several aspects: namely, the application of micro-automatic control systems and various auxiliary equipment in automated molding; the coordination of precision machinery and high-performance hydraulic systems; various special-purpose The development of injection molding machine and computer-aided design analyze the plastic flow of complex-shaped parts to determine the best injection molding conditions; the application of various energy-saving technologies in injection molding machines.

The working principle of injection molding machine

Injection molding machine is abbreviated as injection molding machine. Injection molding uses the thermophysical properties of plastics to add materials from a hopper to a barrel. The outside of the barrel is heated by a heating ring to melt the material. The barrel is equipped with an external power motor to drive rotation Screw, the material is gradually plasticized, melted and homogenized under the double action of the screw shear. When the screw rotates, the material pushes the melted material to the head of the screw under the action of the friction force of the groove and the shear force. At the same time, the screw retreats under the reaction of the material, so that the head of the screw forms a storage space to complete the plasticization process. Then, under the inference of the injection cylinder piston, the screw passes the molten material in the storage chamber at high speed and high pressure. The nozzle is injected into the cavity of the mold. After the melt in the cavity is pressure-maintained, cooled, solidified and shaped, the mold is opened by the clamping mechanism, and the shaped product is lifted from the top of the mold through the ejector device. Fall out.

The composition structure of the injection molding machine

According to the requirements of the injection molding process, the injection molding machine is a highly mechatronics model, mainly composed of injection parts, clamping parts, frame, hydraulic system, heating system, control system, feeding device, etc.

At present, the common injection molding equipment has single cylinder type and double cylinder type.

There are two types of plasticized parts: plunger type and screw type. In the continuous pushing process of the rotating screw, the plastic realizes the change of the physical state, and finally is injected into the mold cavity in a molten state. Therefore, the plasticized component is the core component for uniform plasticization and quantitative injection.