Search This Supplers Products:PET Preform MouldInjection Molding MachinePlastic MouldSemi-automatic Blow Molding MachineAutomatic Blow Molding Machine

- Home

- About us

- Products

- Best selling injection molding machine

- Preformed preform injection mold

- Production injection molding machine

- All kinds of injection plastic molds

- Semi-Automatic Blow Moulding Machines

- Automatic Extrusion Blow Molding Machines

- Produce cheap laser marking machine

- Custom plastic preform injection mold

- Other injection mold forming machines

- Injection Disposable Plastic Tableware Mould

- Faqs

- News

- Certificate

- Contact us

Dry Goods—Avoidance Standards for Injection Mold Design

time2021/03/01

- Mould design is an important part of the development process when considering the production of a new moulding. Some considerations are given below.

Mould design is an important part of the development process when considering the production of a new moulding. Some considerations are given below.

- •

The shape of the moulded part has a direct bearing on the time involved in making the mould, the cycle time of the moulding. For example, undercuts and deep screw threads often require a separate moving part which increases the cycle time of each moulding operation.

- •

Angles on the side walls are necessary to ensure the moulding can be removed from the mould.

- •

The surface finish of the moulding needs to be decided before the mould is completed. Embossing, etching and other finishes can be added to the moulding to enhance the aesthetic qualities of the moulding. Any imperfection on the finish of the moulding will transfer to every mould made.

- •

Weight, surface area and thickness of the moulding directly affect cycle time. Where mouldings have significantly varying thickness, cooling has to be controlled very carefully otherwise depressions form (sink marks) on the outer surface of the moulding caused by excessive shrinkage of the thick section of the moulding.

- •

The number of cavities in a mould is governed by the number of units per annum required. The number of cavities directly affects the size of machine required for the multi-cavity mould; this in turn affects the cost of the mould and the unit cost of the moulding. Where there are many cavities, each one must be uniform compared to the others and the cooling profile needs to ensure that the outer and inner cavities cool at an equal rate, otherwise moulds of differing dimension will result. Hot runner systems are usually used for multi-cavity systems. This reduces the cycle time and amount of waste material formed but increases the overall cost of moulds (see Section 14.6.2).

- •

The need for an insert or label to be inserted during the moulding sequence has to be considered at the mould design stage.

- •

All injection moulds require a point or points at which the molten plastic is introduced into them. If not considered at the design stage, this can leave unsightly surface blemishes on the finished moulding which require a further stage to remove them, incurring extra costs.

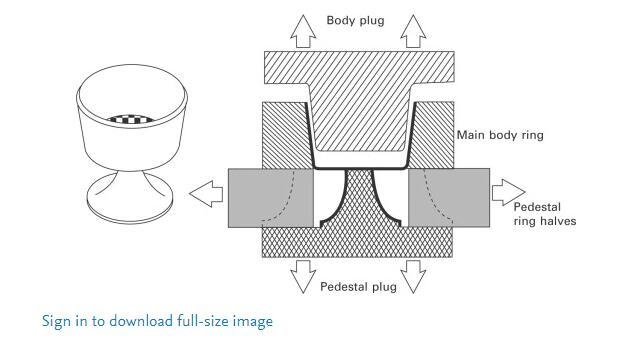

Successful removal of the moulding from the mould is another critical consideration in mould design. Some mouldings, such as closures, have undercuts, which complicates the mould design. Sometimes the moulding is flexible enough, and the undercut small enough to pop or blow it off the tooling without damaging the moulding. However, this is not always the case and a more complex mould design may be required (see Fig. 14.33). Other options are the use of a collapsible core or, in the case of threaded mouldings, the incorporation of an unscrewing device.